SJZ型多功能微電子水處理器是本公司運用現(xiàn)代電子技術(shù)和分子表面能量重新排列技術(shù)研制成功的新一代除垢、防垢、殺菌、滅藻、節(jié)能節(jié)水的水處理裝置。現(xiàn)已在空調(diào)制冷循環(huán)系統(tǒng)、工業(yè)冷卻水系統(tǒng)、各冷卻塔及熱交換系統(tǒng)、冷熱水供水系統(tǒng)易滋生細菌藻類和易生水垢的冷水中得到了廣泛的應用。該產(chǎn)品被國家科委和建設(shè)部推薦為“高新技術(shù)推廣產(chǎn)品”。在此基礎(chǔ)上,我公司還成功開發(fā)了SJZ-Z型自動排污電子水處理器,SJZG-S型手搖式過濾器以及SJZG-Z型自動排污式過濾器。該系列產(chǎn)品科技含量高、安全性能好、效率高、投資小、回收快,深受廣大用戶的好評和贊譽。

.

性能范圍 RANGE OF PERFORMANCE 流量Flow Q:1.25~100m3/h 功率Power:<100~350W

最高工作壓力Max.working pressure:1.0-1.6MPa

進出口徑Inlet and outlet aperture:Φ25~Φ600mm

使用條件CONDITONS OF USE 輸入電源Input power:220V/50Hz

適用水溫Suitable water temperature:0℃~90℃

適用水質(zhì)Suitable water nature:以CaCo3計總硬度小于700mg/L

Total hardness less than 700mg/L counted with CaCO3

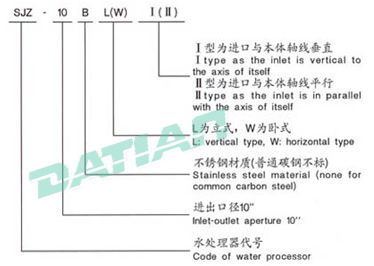

型號意義MODEL MEANING 適用場合 SUITABLE FIELDS

本系列水處理器適用于:各種易滋生細菌、藻類和易生水垢的水系統(tǒng)、空調(diào)制冷循環(huán)水系統(tǒng)、各種熱交換及冷卻塔系統(tǒng)、游泳池系統(tǒng)。

This series water processor is suitable for: various water systems easy to produce bacterial algae and water filth, air-conditioning refrigeration cycle water system, various heat exchange and cooling tower systems and swim-ming pool system.

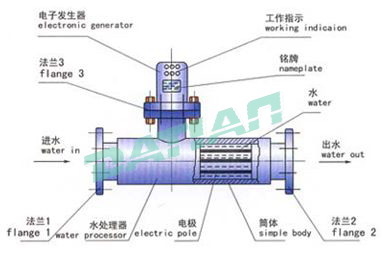

結(jié)構(gòu)簡圖STRUCTURAL DRAWING

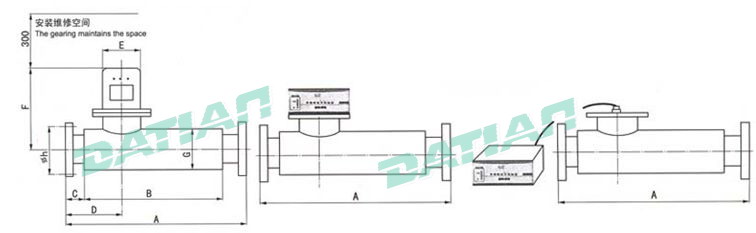

SJZ型性能參數(shù)及外形尺寸圖表SJZ TYPE PERFORMANCE AND EXTERNAL DIMENSIONS FIG. TABLE

| 序號 No |

型號 Type |

出入口尺寸 Out –In dimensions |

流量 Capacity (m3/h) |

A | B | C | D | E | F | G | 輸入功率 Input power (W) |

連接法蘭中心圈Conneet flange centercir Φh/孔數(shù)-螺孔直徑Bore number-Bore diameter |

最高工作壓力Max. work pressure (MPa) | 重量 Weight (kg) | |

| in | mm | ||||||||||||||

| 1 | SJZ-1 | 1 | 25 | 4-5.8 | 620 | 460 | 80 | 200 | 160 | 300 | 100 | <50 | Φ85/4-Φ14 | 1.0 | 20 |

| 2 | SJZ-1.5 | 1.5 | 40 | 9-12.8 | 680 | 520 | 80 | 200 | 160 | 300 | 100 | <50 | Φ110/4-Φ18 | 1.0 | 23 |

| 3 | SJZ-2 | 2 | 50 | 20 | 680 | 520 | 80 | 300 | 150 | 300 | 130 | <100 | Φ125/4-Φ18 | 1.0 | 25 |

| 4 | SJZ-2.5 | 2.5 | 65 | 26-30 | 720 | 560 | 80 | 300 | 160 | 350 | 150 | <100 | Φ145/4-Φ18 | 1.0 | 32 |

| 5 | SJZ-3 | 3 | 80 | 35-52 | 800 | 600 | 100 | 350 | 160 | 400 | 160 | <100 | Φ160/8-Φ18 | 1.0 | 45 |

| 6 | SJZ-4 | 4 | 100 | 65-100 | 800 | 600 | 100 | 360 | 160 | 480 | 160 | <100 | Φ180/8-Φ18 | 1.0 | 76 |

| 7 | SJZ-5- | 5 | 125 | 150 | 1000 | 744 | 128 | 420 | 180 | 570 | 200 | <150 | Φ210/8-Φ18 | 1.0 | 125 |

| 8 | SJZ-6 | 6 | 150 | 145-210 | 1000 | 744 | 128 | 430 | 180 | 570 | 200 | <150 | Φ240/8-Φ22 | 1.6 | 130 |

| 9 | SJZ-8 | 8 | 200 | 260-370 | 1300 | 1020 | 140 | 480 | 260 | 600 | 280 | <150 | Φ295/8-Φ22 | 1.6 | 201 |

| 10 | SJZ-10 | 10 | 250 | 400-590 | 1300 | 1020 | 140 | 520 | 300 | 680 | 330 | <200 | Φ350/12-Φ22 | 1.6 | 268 |

| 11 | SJZ-12 | 12 | 300 | 575-840 | 1400 | 1100 | 150 | 520 | 360 | 750 | 380 | <200 | Φ400/12-Φ22 | 1.6 | 335 |

| 12 | SJZ-14 | 14 | 350 | 785-1100 | 1400 | 1100 | 150 | 540 | 400 | 780 | 430 | <250 | Φ460/16-Φ22 | 1.6 | 430 |

| 13 | SJZ-16 | 16 | 400 | 1030-1480 | 1500 | 1100 | 150 | 540 | 420 | 860 | 480 | <330 | Φ515/16-Φ26 | 1.6 | 508 |

| 14 | SJZ-18 | 18 | 450 | 1300-1860 | 1500 | 1180 | 160 | 580 | 480 | 940 | 520 | <350 | Φ565/20-Φ26 | 1.6 | 628 |

| 15 | SJZ-20 | 20 | 500 | 1610-2300 | 1600 | 1280 | 160 | 600 | 500 | 950 | 640 | <350 | Φ620/20-Φ26 | 1.6 | 765 |

| 16 | SJZ-24 | 24 | 600 | 2300-3000 | 1650 | 1290 | 180 | 660 | 520 | 970 | 750 | <350 | Φ725/20-Φ30 | 1.6 | |

|

|